Woven textiles usually remind us a composition of two directional fabrication.

If so, what would be imagined with “ Triaxial Woven Fabrics” a composition

of horizontal ,vertical and “angled” fabrication ? Triaxial Woven Fabrics form

stable “hexagonal” shapes,and when composed,achieve high durability to tensions

from any directions. Originally inspired from traditional baskets woven patterns,

only SAKASE ADTECH CO., LTD. realized to apply into manufacturing products.

Shapes can be instantly restored from “outward tension,” “inward tension,”“vertical lord,” and “horizontal lord,” even at close to the breaking point.

Besidesof this characteristic ,for being very lightweight and thin-skinned,the material isapplied to products of industries seeking the highest performance, from high-tech sports gears to space craft equipments. This high workability,thin and lightweight durable material must be lead the creativity.

※Weaving System of T.W.F. patented by SAKASE ADTECH CO., LTD.

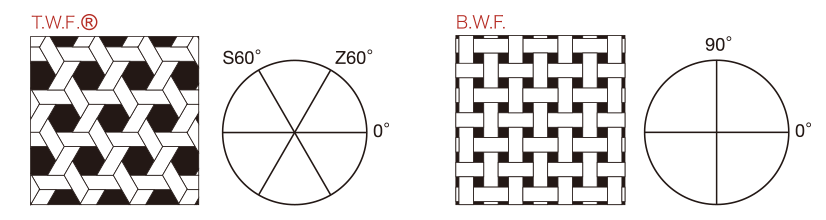

T.W.F. is a fabric formed by a revolutionary new weaving process,in which three yarn ends are woven at 60°angles.Two warp ends and one filling (or weft)end are interwoven at equal angles to produce a fabric having characteristics not found in conventional woven fabric.

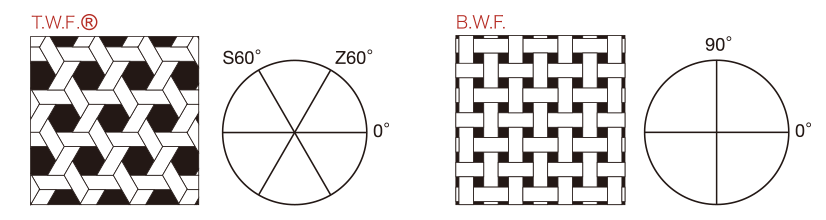

Compared with T.W.F., a conventional woven fabric is formed with two yarn ends interwoven at 90°angles and is being called Biaxial Woven Fabric(BWF)

The performance of fabrics against load is governed by the minimum strength,not the maximum strength of the fabric.The study was started and T.W.F. developed in order to eliminate the weakest direction of fabrics,improve tear resistance,and improve stability in the plane of the fabric.

On the basis of the considerations mentioned above, we are still developing new products of various fields using the unique characteristic of T.W.F. ,which dose not have the structural disadvantages of BWF.