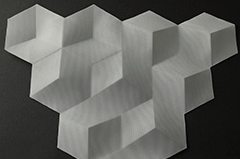

In contrast to conventional(biaxial) woven fabric with two yarn ends interwoven at 90°angles.

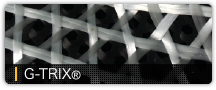

T.W.F.(Triaxial Woven Fabric)is formed by a revolutionary new weaving process,in which three yarn ends are woven at 60°angles.

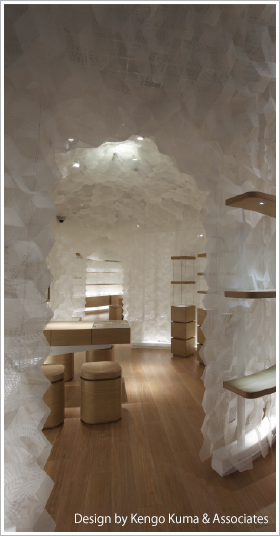

Two warp ends and one weft end are interwoven at equal angles to produce a fabric having characteristics not found in conventional woven fabric : a light-weight, heavy-duty, tear-resistant fabric. Using a conjugate fiber with a high melting-point core and a low melting-point sheath, the fabric can be molded using a heat press process.

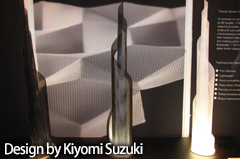

Especially, T.W.F. has excellent flexibility on curved surface, and can be molded deep drawn shape.

![]()

◎Thin Skinned ◎Lightweight ◎Good workability to Shape ◎Deep Drawn Shape Available

◎Flexible on curved Surface ◎Stable Dimentions ◎Shape Restoration